Inventory Management

Inventory Management ensures that materials and products flow efficiently throughout the manufacturing process, optimizing stock, reducing waste, and ensuring timely deliveries through smart planning and logistics.

Have full control over materials and ensure an efficient production flow.

Raw Materials Management provides complete visibility over the location, condition, and disruptions in the flow of materials. This approach helps reduce delays caused by stock queues and improves communication between departments, ensuring that the right materials are available at the right time for production.

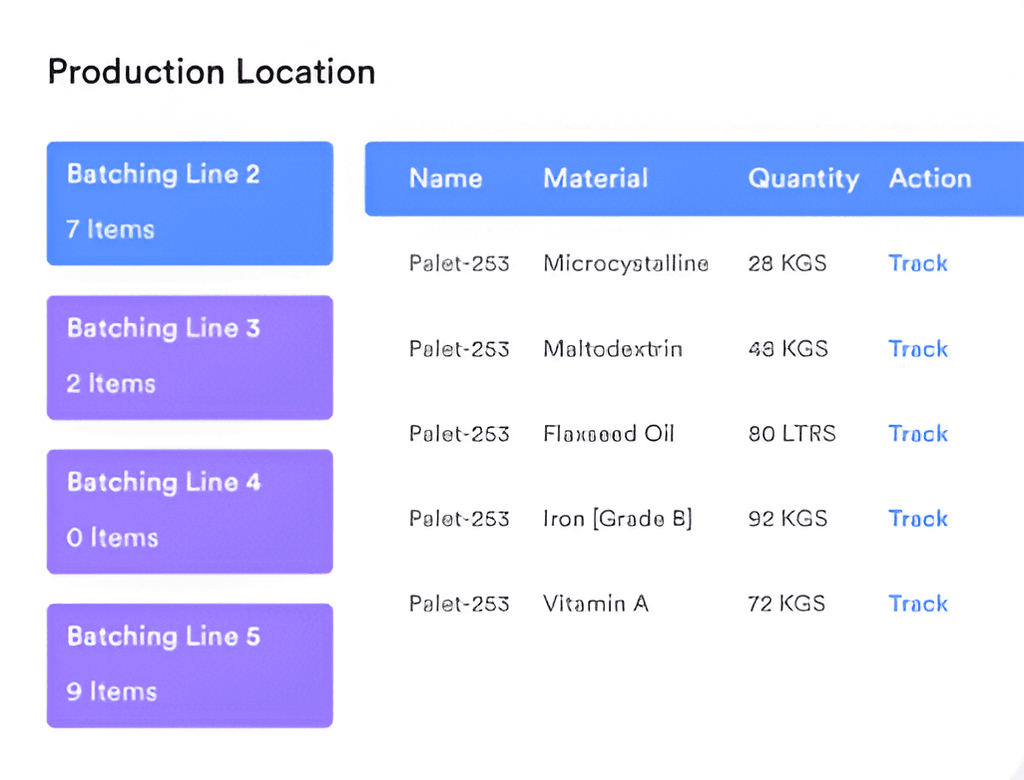

Track production progress in real time and eliminate inefficiencies in the flow of materials.

Work-in-Process Management provides full visibility into the location, status, and disruptions in the flow of materials during the production process. This capability helps reduce delays caused by inventory queues or communication failures, ensuring a continuous and efficient flow between the different stages of production.

Ensure availability, reduce stockouts, and guarantee timely deliveries based on real-time data.

Finished Product Management allows you to determine the quantities needed to fulfill orders and monitor, in real time, exceptions such as delays or partial quantities. Through the analysis of consumption patterns, it is possible to predict stock shortages and anticipate needs, ensuring a continuous flow between production, warehouse, and distribution.

Have full visibility of production and respond quickly to critical events.

Material Traceability allows tracking materials throughout the entire production process, from the supplier to the final product. It is possible to monitor batch codes, process routes, operator interventions, dates and times, quality test results, and process parameters, ensuring full visibility and compliance at every stage of production.

Increase supply chain efficiency with data that drives smart decisions.

Supply Chain Metrics and Reports provide complete visibility over warehouse planning and inventory indicators, enabling improvements in logistics and supply chain performance. Based on real-time data, it is possible to identify areas requiring corrective actions, reduce the time between order and shipment, and increase on-time delivery rates.